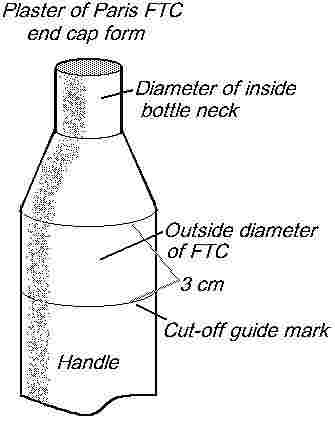

Bottle Neck Caps For Fluorescent Tube Covers

A technique for making ends for water rockets using

fluorescent tube covers and 500 ml Dr Pepper bottles.

Fluorescent tube covers are long plastic

(polycarbonate)

tubes sold in hardware and lighting stores. They are designed to

slip over Fluorescent light bulbs to prevent a broken bulb from

showering

anyone below it with broken glass. Readily available in the USA,

they might be difficult to find in countries with fewer or different

safety

regulations. Needless to say, being extremely tough, about 42 mm

(1 3/8 in) in diameter and coming in lengths over 2 meters (8 ft), it

was

only a matter of time before a water rocketeer noticed this material.

There are reportedly some good fits to FTC using

commercial model rocket nosecones. This will work fine if you

don't

need to put anything on top of your rocket, but it will get expensive

unless

you are using water recovery.* The following describes a method I

use based on the conical shape of 500 ml Dr Pepper bottle neck.

*It is possible to trim one of these rockets so that

it descends horizontally

at a non-dangerous speed, but I suspect this will ultimately cost you

altitude.

Make a mold for plaster of paris by drilling a

carefully

centered 1 3/8 inch hole in the bottom of a Dr Pepper bottle

using

a spur drill (A spade drill bit with spikes at the corners of the

cutting

edge.) Smear Vaseline inside the bottle neck as a release

agent,

cap the bottle and insert a square cut piece of FTC that is long enough

to stick out the bottom of the bottle. Pour plaster into the FTC

and let it harden. If you are smarter than I am you might think

about

how you are going to hold this assembly while the plaster sets before

you mix the plaster. When it is hard, you can twist and pull the

form out of the bottle, but leave the FTC on the plaster. Clean

off

any plaster that might have leaked out around the FTC inside the

bottle.

I made a line 3 cm from the shoulder on the FTC to guide my scissors

when

I trim bottlenecks before shrinking them.

Cut

off the neck of a Dr. Pepper bottle at the shoulder, slip it onto the

plaster

form, trim it to the line, and shrink it with a heat gun. You

will

find this makes a snug fit with FTC in a minute or so.

Cut

off the neck of a Dr. Pepper bottle at the shoulder, slip it onto the

plaster

form, trim it to the line, and shrink it with a heat gun. You

will

find this makes a snug fit with FTC in a minute or so.

The contact surfaces inside the neck and outside

the FTC are roughened with coarse sand paper, and I glue them together

with Household Goop because it is hard to find the superior but uglier

PL Premium where I live. Using Goop, it is easy to level the glue

squeezed out with a moistened finger. Use rubber gloves if you

handle

PL Premium at all.

Using this technique, it is easy to put two nozzles

on an FTC. Thinking about it another way, it is also easy to put

on a nozzle and a threaded fitting. I glue (Goop again) two

bottle

caps together, back to back, and put a Pop rivet through them.

Use

a washer to get the rivet tight. This makes an air-tight

female-female

adapter. Then anything I can make based on the male threaded neck

of a bottle, for example, payload chambers or recovery systems,

securely

screws onto the front of my rocket. I make a fairing from another

bottle or short piece of FTC to cover the linkage. These rockets

are modular, and it is

easy to switch and swap parts.

7/25/00 Gordon B. McDonough