The InterPlanetary Water Rocket Society

Notebook

Rev. 6/8/05

Water Rockets at

School

Other

Water Rocket Sites on the Web

Contents:

A

comment from my friend

Jean

Berthelot has inspired me to post a picture of my

rockets.

These rockets are usually Dr Pepper bottles with conical necks.

Some

have been shrunken from 500 ml to 400 ml using boiling water. The

two tall bottles on the left are joined bottom to bottom for larger

motor

volume. The noses are half tennis balls, attached using hot melt

glue and colored electrical tape. The fins are corrugated plastic

sign board friction fitted into report cover spines. The spines

are

glued to the bottles with either low temp hot melt glue (faster) or

Household

Goop (stronger). Recovery is ballistic, the fins typically pop

off

without damage. These rockets fly fast and very high. They

make a very exciting whistling sound as they come home, discouraging us

from trying to catch them.

They do not fly as fast or

as high as my fluorescent

tube cover rockets fly.

Gliding

Calistoga Rocket

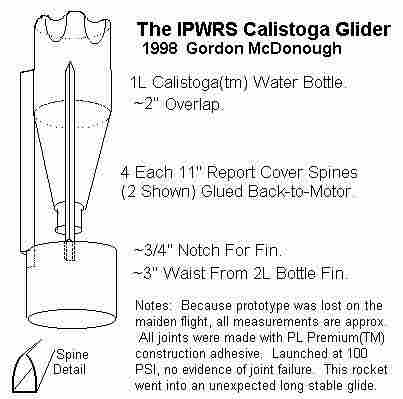

This

rocket took

off vertically at 100PSI and went into a flat stable glide. It was lost

some 300 feet from the launch site on the roof of a building. A sketch

with approximate dimensions follows. I have seen and heard of behavior

similar to this several times since with similar rockets.

More recent launch

successes

have involved smaller bottles, tubular fins or corrugated plastic fins

inserted in the report cover spines, and a half tennis ball nose.

See Above.

In 2005, The Alameda Middle School Water Rocket Group built a number of

gliders with two liter bottles and typically oversized fins glued

directly to the bottles. We hot glue tack the fins to the

bottle, and then reinforce the joint with PL Premium construction

adhesive. Bottles that glided typically had fins half way up

their length.

We

also had a great success cutting the neck off a three liter bottle,

inserting and gluing (PLP) a two liter bottle neck inside it, and with

oversized (by eye) fins, at about 100 psi convinced this one to fly out

of sight. We never did get it back as it sailed off into the

neighborhood behind the bleachers. We were launching from the

center of the football field in the school's rocket range.

|

Return To G. McD's Home

Page

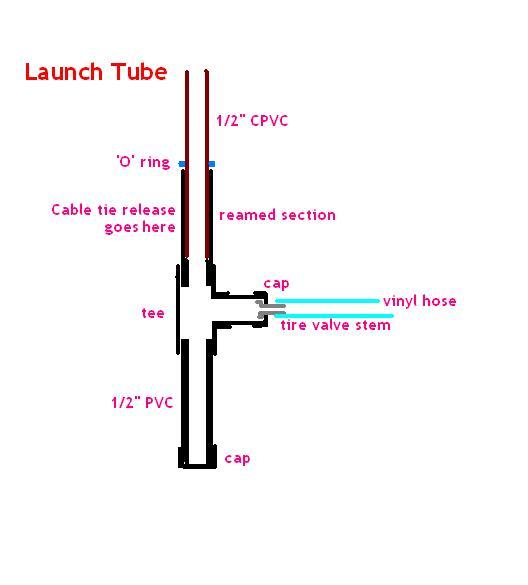

Why Tube Launchers?

They are elegant and

effective.

During any open nozzle* launch, the water is expelled in a tiny

fraction

of a second. Acceleration is almost immediate, and the rocket's flight

is almost entirely ballistic. This all starts with both the rocket and

it's 'fuel' standing still. With a tube launcher, the initial thrust

takes

place with very little loss of water, and lasts the length of the

launch

tube. At that point, not only the rocket but also it's considerably

more

massive fuel are already traveling at speed. Any loss of pressure up to

this point is partially offset by air entering the rocket from the

launch

tube.

*An open nozzle launch uses the original

dimensions

of the bottle's mouth for the nozzle. This is not the only way to

launch

these rockets, nor is it going to result in the highest performance. It

is

probably the easiest. Some people like to fasten other sorts of nozzles

inside the bottle mouth. (There is agreement in the water rocket

community

that an open mouth is a maximum desirable opening.) An intriguing

alternative

is the so-called T-nozzle, which employs a full size launch tube for

initial

acceleration, but then a fitting drops into the nozzle to reduce and

extend

the thrust over time. For something with as little mass and as much

drag

as a soda pop bottle, this can make a lot of difference.

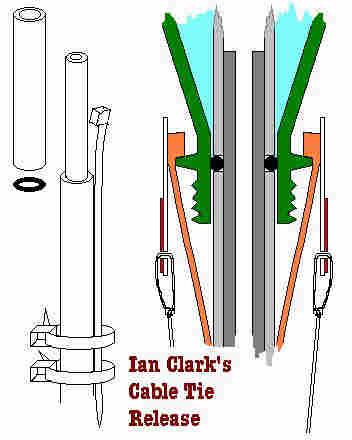

Cross-Section Key:

WaterMotorLaunch Tube

Sleeve'O'

Ring

Cable TiesRetainerTape

This drawing portrays my version of Ian

Clark's

Cable Tie Release. Cable ties are used by electricians to bind wires

together.

I have only shown one on the left, but I use as many as fit around the

launch tube. There is a #94 rubber 'O' ring between the upper and lower

parts of the launch tube. The upper part of the launch tube is snug on

the inner sleeve, but is removable to exchange with others of lengths

appropriate

to my motors. (Long motor / long tube.) The ties are held engaged with

the collar on the motor by a ring of flourescent tube cover about two

inches

long. To increase visibility from the pumping station, there is red

electrical

tape around the ring. The ring is light enough to hold itself up with

friction

before pumping starts. The pull down strings go to a metal ring. The

remote

release string is tied to a second ring on the launcher base, it passes

up through the upper ring, back down through the lower ring and out

horizontally

to the launch crew.

Assembly is a bit tricky. I use light rubber

bands

and masking tape to hold the ties while I position them. I place a

bottle

on the launch tube to line up the tie heads with the bottle's collar.

When

everything looks right, I put some cable ties around the rest (Drawing

on the left), and tighten them. If everything still looks good, I smear

warm epoxy all over this section. (Warm so it flows better.) Then I

trim

all the ends flush. If one desires to experiment with different bottle

placings, one can use hose clamps without the glue, but it results in a

clunky looking job and the clamp can get in the way of the retaining

ring.

Top

Contact me, Gordon McDonough, at gordo@hubwest.com